Hems are folded-again edges on sheet metal components, which may be opened or shut. Occasionally, becoming a member of two hems also functions as fasteners. Bend sheet metal with making certain the subsequent criteria;

The overall length with the flat portion somewhat decreases after the functions since the bent portion stretches some materials. Right here, you'll want to deduct some duration to get the full flat duration, referred to as bend deduction.

These precision-engineered seals are designed to protect against oil leakage from hydraulic cylinders along with other pressurized compartments, ensuring steady general performance and longevity on the equipment.

The metal sheet is fed concerning the upper roller and the two mounted rollers. As The 2 fastened rollers rotate, they grip the sheet, even though the adjustable roller applies downward pressure to achieve the demanded curvature.

In a least, the smallest bend radius should be at least equal into the sheet thickness to prevent fractures or distortions during the metal section.

If alignment challenges persist, a radical inspection with the ram’s area problem and manual system is necessary, with probable adjustments towards the Y axis as necessary.

From The essential ideas and classification to the Visit this page purposes and advantages of metal and sheet metal forming, this quick read through has it all!

“Press” emanates from the word “presse,” which was used being a noun indicating “to crush or to group”; the expression advanced to necessarily mean a machine or tool that applies drive by squeezing.

It’s value noting which the time period “press crack” is incorrect as nothing is staying damaged or shattered.

Always use a press brake wherever applicable as it provides aid and guarantees cleaner sheet metal bending and continual pattern throughout bent sheets.

Uncover a close-by distributor or reseller

Given that the fourth industrial revolution is upgrading the business, we established out on a mission to equipour purchasers to choose comprehensive benefit of this Enhance in manufacturing quality and performance.

Press brake clamps are vital factors within the tooling system, comprising common clamps and brief-change clamping units created for immediate leading punch exchanges. These clamping systems Engage in a vital purpose in optimizing the set up process and enhancing Total productiveness.

Tabs and notches will be the sheet metal functions mostly utilized for joining needs. A tab is a small extension on the edge, whereas a notch is a small Reduce-out. They might weaken the fabric in case of inappropriate positioning. So, take into consideration the subsequent style and design procedures;

Haley Joel Osment Then & Now!

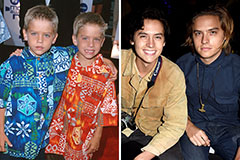

Haley Joel Osment Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Soleil Moon Frye Then & Now!

Soleil Moon Frye Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now!